Xiaomi’s Automated Electric Vehicle Factory: A Milestone in Automotive Manufacturing

Xiaomi, the renowned tech giant, has recently unveiled its state-of-the-art electric vehicle factory during the launch of the Xiaomi SU7 electric car. Located in the Beijing Economic-Technological Development Area, the factory covers an impressive area and comprises six main workshops, 29 R&D laboratories, and a 2.5 km test track.

A Factory Built in Record Time

The construction of Xiaomi’s electric vehicle factory was divided into two phases. The first phase, covering nearly 720,000 square meters, commenced in April 2022 and was completed in June 2023. The second phase is scheduled to begin in 2024 and be finished by 2025. The completed sections include manufacturing plants, testing facilities, and production lines for stamping, welding, painting, assembly, and battery production. These plants successfully passed inspection on June 12.

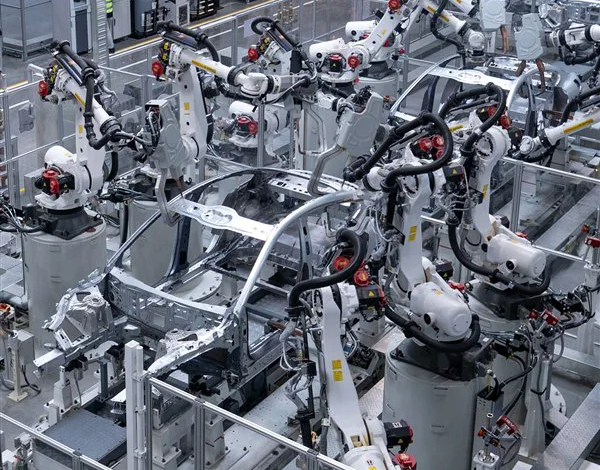

The Epitome of Automation

Xiaomi’s factory is equipped with over 700 robots that enable 100% automation across critical processes such as steel and aluminum chassis assembly, door and trunk lid installation, automated transport of medium to large-sized components, and cutting-edge 7-axis robotic painting systems.

Quality control procedures are also entirely automated, encompassing UV checks for exterior surfaces, laser radar inspections for chassis integrity, and X-ray inspections for casting details.

With this advanced production line, Xiaomi expects to produce a new Xiaomi SU7 electric car approximately every 76 seconds once it reaches maximum capacity.

A Commitment to Environmental Sustainability

Xiaomi’s factory incorporates several environmentally friendly features. The workshop roofs are covered with solar panels, generating 16.4 million kWh of electricity annually. The facility boasts a 99% effective exhaust treatment system and utilizes recycled aluminum in high-pressure die casting.

Meeting the Demand: A Challenge for Xiaomi

The demand for Xiaomi’s electric vehicles has been overwhelming. According to an official announcement on Weibo, the SU7 model achieved sales of over 10,000 units in just 4 minutes, 20,000 units in 7 minutes, and 50,000 units in 27 minutes.

However, Xiaomi is currently facing production capacity issues. “Initial production capacity is insufficient. There are many pre-orders, but delivery times remain uncertain,” confessed a Xiaomi employee to Sina Technology.

CEO Lei Jun has long been concerned about long waiting times and its potential impact on Xiaomi’s reputation. In a previous interview, he stated, “I worry that if everyone buys our cars and has to wait for one or two years, it will affect our reputation.”

To address this challenge, Xiaomi plans to produce 2,000 vehicles per month by March and aims to exceed 10,000 units monthly by July.

Xiaomi’s automated electric vehicle factory represents a significant milestone in the automotive industry, showcasing the company’s commitment to cutting-edge technology, environmental sustainability, and exceptional manufacturing capabilities.

For more information on Xiaomi and its innovations, visit Business Today.